| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : TISCO,BAO STEEL

Model Number : 42CrMo / 4140 SCM440

Certification : SGS,ISO

Place of Origin : CHINA

MOQ : 3 Ton

Price : 650-900 USD/Ton

Payment Terms : T/T or L/C

Supply Ability : 5000 Tons every month

Delivery Time : 7 days

Packaging Details : Export packing

name : steel round bar

Dia : 20-520mm

length : 6-11m

type : hot rolled / cold rolled

alloy or not : alloy

grade : 42CrMo / 4140 SCM440

Technique : Hot Rolled,Forged

Delivery condition : annealed,within15 days after received the deposit

42CrMo SCM440 Forged Steel Round Bar

Gnee is the most acclaimed manufacturer, exporter, distributor and supplier of industrial 42CRMO4 forged alloy steel round bar with required test certificates

42CrMo Forged Round Steel Bars (60MM-800MM)

| Equal grade | GB | DIN | ASTM | JIS | BS | NF | |

| 42CrMo | 1.7225 | 4140 | SCM440 | 708M40 | 42CD4 | ||

| Chemical Composition (%) | C | Cr | Si | Mo | Mn | P | S |

| 0.38-0.43 | 0.8-1.10 | 0.15-0.35 | 0.15-0.25 | 0.40-0.70 | ≤0.030 | ≤0.030 | |

Product specification

42CrMo Forged Round Steel Bars (60MM-800MM)

a.Specification:80mm up & as client requrement

b. Length:3m-5.8m

c.Technique:Forged

d.smelting processing:EAF+LF+VD

42CrMo / 4142 SCM440 steel bar stock , hot rolled alloy steel round bar

Specifications

42CrMo / 4140 Steel Round Bar

ISO9001 certified

Flexible MOQ

Prompt delivery stock within 7days

MTC DIN10204 3.1/3.2

Equivalent grades

| GB | DIN | AISI | JIS |

| 42CrMo | 1.7225 | 4140 | SCM440 |

Chemical Composition

| C | Si | Mn | Cr | Mo | P | S |

| 0.38-0.43 | 0.40max | 0.60-0.90 | 0.90-1.20 | 0.15-0.30 | ≤0.035 | ≤0.035 |

Available size

| Round steel bar 60-800mm | |||||||||

| Flat steel bar 25-400mm*200-800mm |

Surface condition

| Black surface/ Grinded/ Machined |

Hardness

| Annealed HBS 217 max |

CharacteristicsApplications

| 42CrMo / 4140 Steel Round Bar is used to producecomponents with high requirements on toughness, e.g. gear wheels, pinions, connecting rods, parts for mechanical engineering . |

Heat treatment

| Forging | Heat to 1150°C. Hold until uniform. Minimum forging temperature 850°C.Cool slowly in ashes or sand etc. | ||||||||

| Annealing | Heat to 830°C-850°C.Cool in furnace. | ||||||||

| Normalising | Heat to 870°C-900°C.Cool in still air. | ||||||||

| Stress Relieving | Annealed: Heat to 600°C-650°C.Hardened: Heat to 500°C-550°C.Cool in still air. | ||||||||

| Hardening | Heat to 830°C-880°C. Quench in oil or polymer. | ||||||||

| Tempering | Heat to 450°C-700°C cool in still air. NB. Tempering within the range 200°C-420°C will result in temper brittleness and should be avoided. | ||||||||

|

|

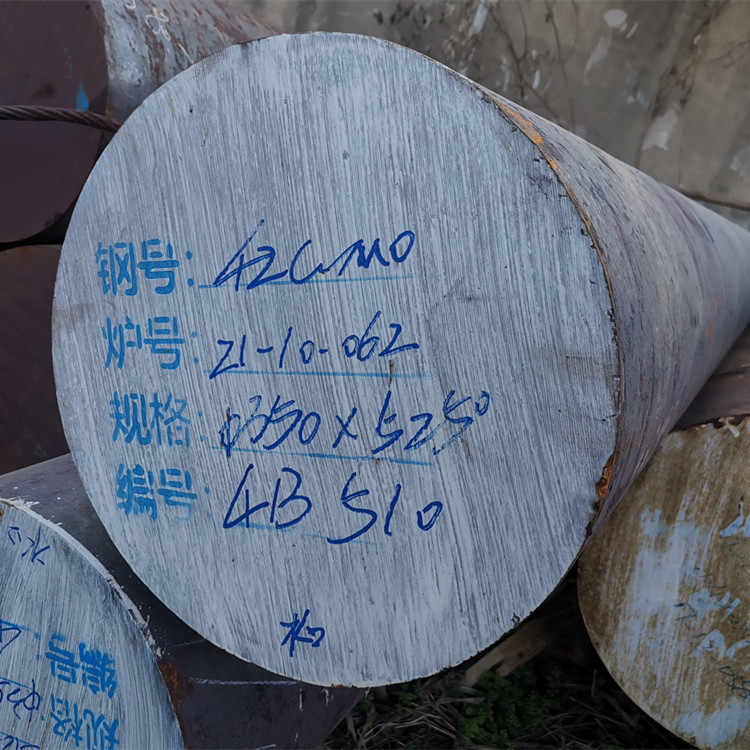

OD350mm Steel Round Bar SAE 4140 SCM440 Hot Rolled Forged Images |